A DIP switch (Dual In-line Package switch) combines several switches into one unit. It is an electromechanical device that needs an actuator to be physically moved by the user to activate or deactivate a different electrical circuit. Frequently installed on a PCB (printed circuit board) or breadboard (a terminal or base used to build circuits) lets users quickly preconfigure or switch an electronic device between several settings or operational modes. Read More…

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of electric switches, membrane switches, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes.

At ALMAX, we specialize in the design and manufacturing of electronic switches that merge precision engineering with customizable interface solutions. Our products are engineered to serve a wide range of industries, from medical device manufacturers to aerospace, industrial controls, and consumer electronics.

At CSI Keyboards, Inc., we have built our reputation around engineering electric switches that combine precision, reliability, and adaptability for a wide range of applications. Our switches are designed to meet the demands of industries where durability and accuracy are critical, from medical devices and industrial equipment to commercial electronics and beyond.

ABB is a manufacturer of low-voltage electrical switches. We offer relaying products, automation products—limit switches, rotary switches, toggle switches, disconnect switches, cam switches and safety switches for construction, process industries, industrial and OEM markets.

At Schneider Electric, we design and manufacture advanced electric switches that bring efficiency, reliability, and innovation to power control and automation systems worldwide. Our switches are engineered to meet the diverse needs of industrial, commercial, and residential environments, offering precise performance, safety, and durability.

At Powell® Electronics, we are dedicated to providing our customers with the best products and services possible. We understand that each customer has unique requirements, and we are committed to meeting those needs with high-quality products and exceptional customer service. Whether you need a standard electronic component or a custom-designed solution, we have the expertise and experience to...

Electric switches for industrial, residential and commercial uses are manufactured by Leviton Manufacturing Company. We offer switches with Amp ratings of 15, 20 and 30; they can include motor starter, lighted handle or pilot light, single-pole, double-pole, three-way and four-way.

More DIP Switch Manufacturers

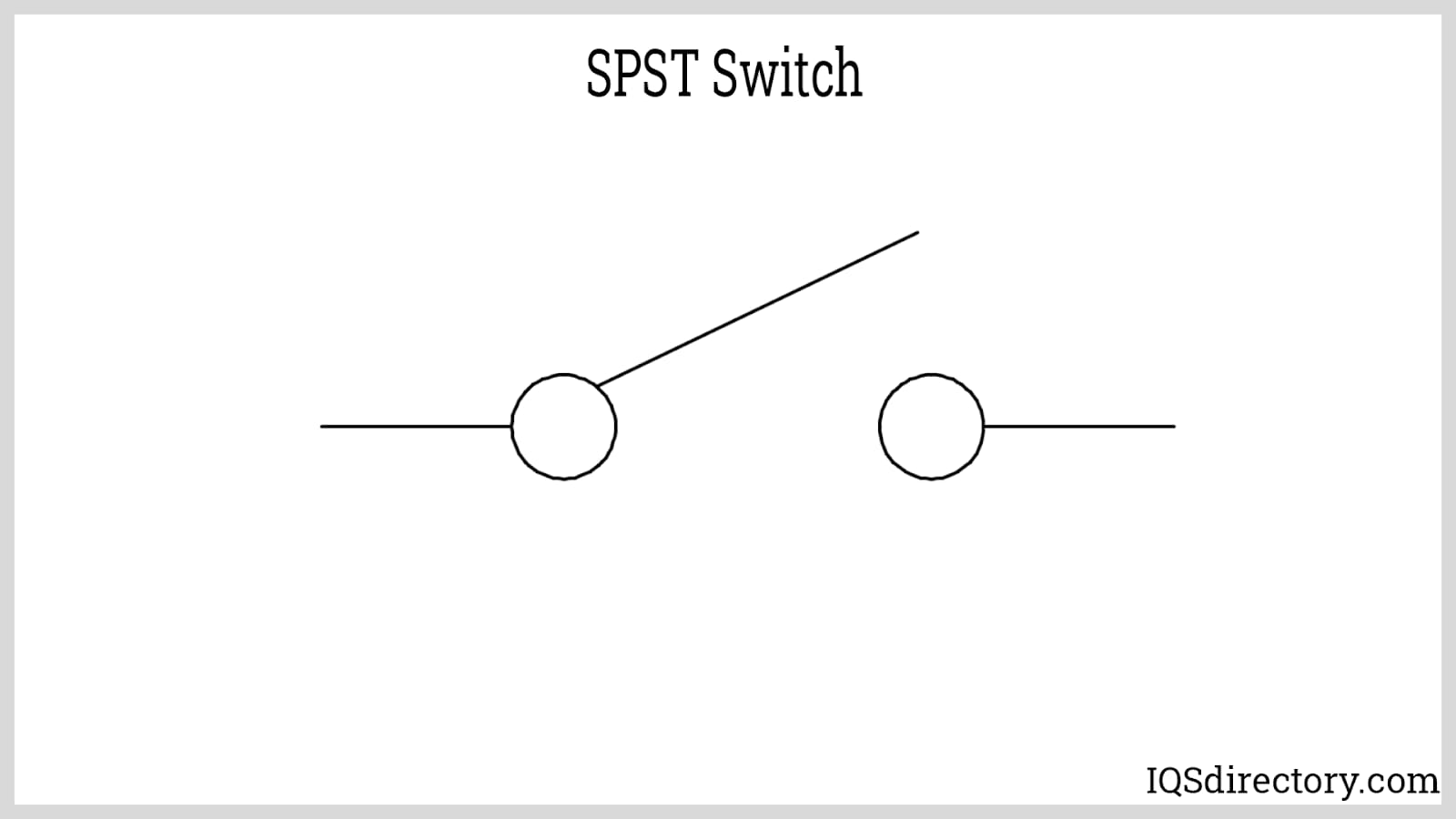

The principle of poles (the number of circuits controlled by a switch) and throws (the number of "ON" positions each switch has) is fundamental when discussing any type of electrical or electronic switch, especially in the context of DIP switches and related electronic switching devices. A single pole, single throw (SPST) switch is the simplest type of switch, used to either close (permit current to pass) or open (prevent current flow) in an electronic circuit. SPST switches are common in basic on/off applications and are a core building block in digital logic design, embedded systems, and circuit prototyping.

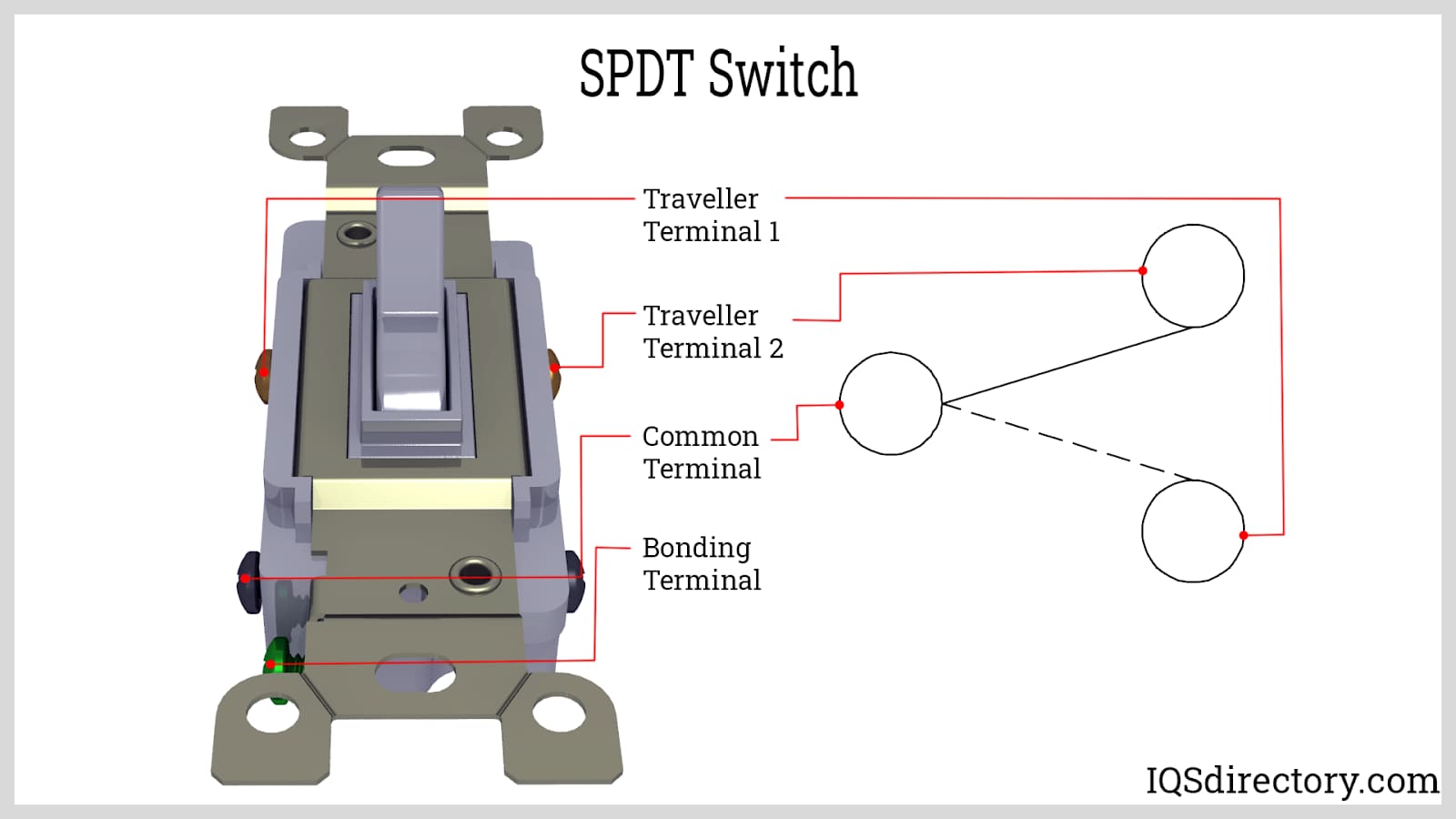

A single pole, double throw (SPDT) switch chooses one of two possible current-flow directions. In other words, shifting the actuator directs current flow in a different circuit branch rather than interrupting it. SPDT switches are frequently used when you need to alternate between two circuits, such as in the selection of signal paths, toggling between power sources, or switching device modes. They are widely implemented in communication equipment, test and measurement instruments, and industrial automation controls.

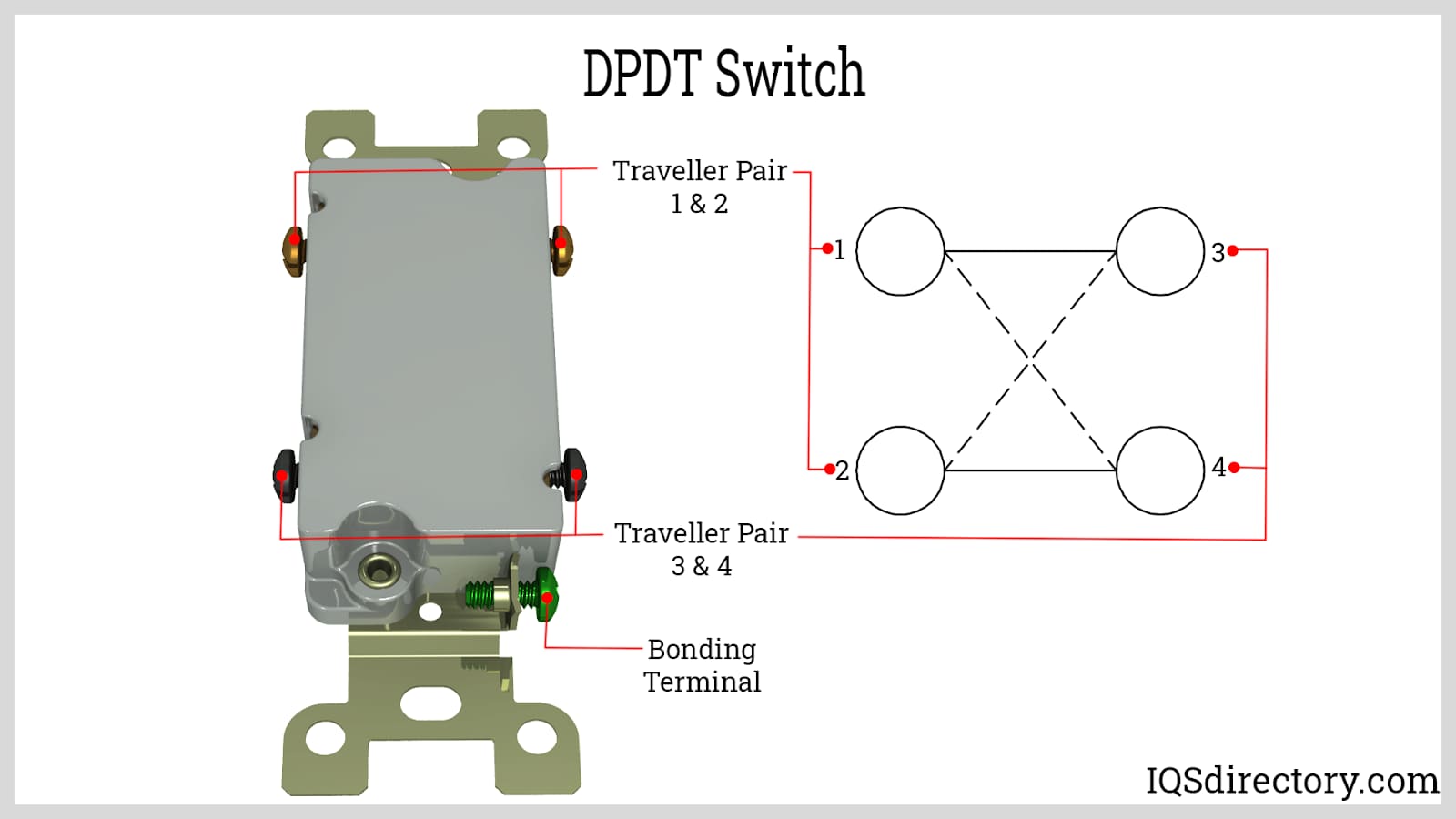

Double pole, double throw (DPDT) switches use two connected switches to regulate two circuits. Both switches change positions simultaneously when one is toggled. Within its circuit, each switch diverts the current in a different direction. Technically, this configuration allows for numerous poles and throws by connecting several switches. DPDT switches are essential in applications requiring polarity reversal, such as DC motor control, switching between different power supplies, or advanced signal routing in audio and telecommunication systems.

Depending on the application, a switch package may contain 1 to 16 (or more) switch positions. For example, a DIP switch package is typically made of eight positions because switches can use 256 binary codes to represent one data byte. DIP switch arrays are designed for configuring circuit boards, programming logic controllers, and setting device addresses in networked environments, making them invaluable for electronics engineers and system integrators.

Types of DIP Switches: Comprehensive Guide for Engineers and Buyers

There are many types of DIP switches available. Below, we discuss a few common DIP switch designs and their ideal use cases, applications, and selection criteria. Understanding these types is essential for engineers, designers, and procurement specialists aiming to optimize their circuit design, device customization, and system integration projects.

Toggle DIP Switch

Toggle switches are one of the most commonplace DIP switches. These switches are operated by pushing or flicking up, down, left, or right to open or close a circuit. Since toggle DIP switches only have closed or open positions, they function as SPST switches. Toggle DIP switches are frequently used in basic on/off circuit control, device configuration, and prototyping. Their tactile feedback and reliability make them popular in industrial automation, home appliances, and security systems where manual configuration is required.

Piano DIP Switch

A piano DIP switch features a series of "keys" spanning across the unit, which are pushed down to actuate various circuits. The design mimics the appearance of a piano keyboard, making it easy to operate multiple switches simultaneously. Piano DIP switches are ideal for compact electronics, such as handheld devices, remote controls, and consumer electronics, where space-saving and user-friendly configuration is a priority. Their robust construction ensures longevity, even with frequent switching cycles.

Rotary DIP Switch

Rotary DIP switches toggle positions as the operator rotates the actuator in a circular motion. The switch's output is based on how much it rotates, enabling multiple positions and configurations. Up to 16 alternative binary output configurations can be produced by a rotary DIP switch with four output pins. A DIP switch can also be set up as an SPDT device, and a single pole may receive three or four throws. Rotary DIP switches are widely used in address setting for communication devices, industrial controllers, and test equipment due to their clear position indication and high reliability in critical settings.

16-Position Rotary DIP Switch

A 16-position rotary DIP switch's output combination is specified by a hexadecimal code consisting of 16 symbols. Numbers 0 to 9 are followed by letters A to F to form the hexadecimal code. This extensive range of positions makes 16-position rotary DIP switches ideal for applications requiring unique device addressing, such as node selection in multi-device networks, configuration of industrial automation modules, and advanced settings in programmable logic controllers (PLCs).

Slide DIP Switch

There are also three-position slide DIP switches, commonly set as on/off/on, with a neutral location in the middle and contacts at either end. Slide switches are favored for their easy operation and clear state indication. Any DIP switch can function as normally closed (NC) or normally open (NO). When activated, normally open switches complete the circuit, whereas normally closed switches sever the circuit. Slide DIP switches are used in consumer electronics, telecommunication equipment, and test boards for quick and reliable manual configuration changes.

Rocker DIP Switch

Other varieties of DIP switches include seesaw-style rocker actuators. Lifting one side of the actuator lowers the other when the switching mechanism is in any of its two locations. They are merely another variant of the standard toggle switches as a result. Rocker DIP switches are commonly chosen for their durability and ease of use in applications such as industrial control panels, HVAC systems, and medical equipment, where positive actuation and visual feedback are crucial.

Key DIP Switch Specifications

Actual performance and specification details for each DIP switch are available in manufacturer datasheets. This knowledge is essential for selecting the ideal DIP switch for a certain application. In addition, there are other parameters to keep in mind besides the obvious ones, like the number of positions and actuator type. Key specifications to consider include:

- Electrical Rating: Maximum voltage and current the switch can handle.

- Contact Resistance: The resistance encountered by current as it passes through the closed switch.

- Insulation Resistance: The resistance between open contacts, crucial for preventing leakage currents.

- Mechanical Life: Number of switching cycles the DIP switch can perform before failure.

- Actuation Force: The amount of force required to operate the switch, important for user experience and automation.

- Package Size: Dimensions of the DIP switch, relevant for PCB layout and space-constrained designs.

- Pin Configuration: Arrangement and number of pins for compatibility with various circuit boards.

- Mounting Type: Through-hole, surface mount (SMD), or panel mount options, impacting assembly methods.

- Environmental Ratings: Tolerance to temperature, humidity, dust, and vibration for reliability in harsh environments.

- Compliance and Certification: RoHS, REACH, UL, CE, and other certifications for quality and regulatory adherence.

When researching which DIP switch is best for your project, ask questions such as: What is the required voltage and current rating? How many positions are needed for configuration? Is a specific actuation method (toggle, slide, rotary, rocker, piano) preferred? Are there environmental or industry compliance requirements? Use datasheets and technical support from reputable DIP switch manufacturers to compare options effectively.

DIP Switch Applications: Use Cases and Industry Solutions

For many years, DIP switches have been utilized in a wide range of applications. As a quick approach to preconfigure or reprogram a device before it is implemented in a smart home or factory, DIP switches have even discovered new uses for IoT (Internet of Things)-compatible devices, helping limit downtime and streamline deployment. The following are some of the most typical uses for DIP switches in modern electronics, automation, and industrial control:

- Setting up garage door openers: DIP switches provide unique code settings for security and access control.

- Configuring remote controls: DIP switches are used to match transmitters and receivers in home automation and commercial systems.

- Establishing options on motherboards or expansion cards for computers: DIP switches enable hardware-level configuration for device compatibility, overclocking, and system customization.

- Adding devices to an IoT network: DIP switches offer device addressing and mode selection for seamless network integration.

- Performing configuration checks on industrial equipment without turning it on: DIP switches allow engineers to set or verify device parameters safely and efficiently during maintenance or installation.

- Programmable logic controllers (PLCs): Used for setting device IDs and baud rates in automation networks.

- Test and measurement instruments: DIP switches configure input ranges, function modes, and calibration settings.

- Security and alarm systems: DIP switches set alarm codes, zone settings, and system modes for tailored security configurations.

- Consumer electronics: Employed in devices like clocks, thermostats, and audio equipment for user configuration.

- Communication infrastructure: Network equipment uses DIP switches for selecting address, frequency, and protocol settings.

Want to learn how DIP switches can improve your next project? Explore guides on DIP switch integration, configuration best practices, and troubleshooting tips to maximize device performance.

Benefits of DIP Switches: Why Choose DIP Switch Technology?

DIP switches offer several significant advantages for engineers, manufacturers, and end-users:

- Cost-effectiveness: DIP switches are affordable and economical for large-scale production and prototyping.

- Reliability: Mechanical operation ensures predictable performance with minimal maintenance.

- Ease of Use: Users can quickly reconfigure devices without specialized tools or software.

- Flexibility: Available in various forms—toggle, slide, rotary, rocker, and piano—to suit diverse design requirements.

- Compact Form Factor: Space-efficient design allows for integration into small and densely populated PCBs.

- Direct Hardware Control: Enables hardware-level settings that are immune to software bugs or firmware corruption.

- Long Service Life: High-quality DIP switches can endure millions of cycles, supporting longevity in mission-critical systems.

- Customization: Multiple switch positions enable countless configuration combinations for unique device requirements.

- Instant Feedback: Physical actuation provides immediate confirmation of configuration changes.

Considering DIP switches for your project? Compare their advantages with alternative configuration methods like jumpers, software menus, or tactile membrane keypads to determine the best fit for your use case.

Decision Factors: How to Select the Best DIP Switch for Your Application

Selecting the right DIP switch is a critical step in ensuring optimal performance, reliability, and user experience. When evaluating DIP switch options, consider these key decision factors:

- Application Requirements: Define the exact purpose of the DIP switch—configuration, device addressing, mode selection, safety interlock, etc.

- Electrical and Mechanical Ratings: Match the switch’s voltage, current, and actuation force with your circuit specifications.

- Form Factor and Mounting Style: Choose DIP switches that fit your PCB layout, enclosure, and assembly process—through-hole or surface mount.

- Number of Positions: Determine the number of switch elements required for sufficient configuration options.

- Environmental Conditions: Consider temperature, humidity, vibration, and contamination factors.

- Certifications and Compliance: Ensure the switch meets necessary industry standards, such as RoHS, UL, or CE, for your region or application.

- User Accessibility: Evaluate how easily end-users can access and operate the DIP switches for maintenance or reconfiguration.

- Supplier Reliability: Work with trusted manufacturers offering comprehensive datasheets, technical support, and consistent product quality.

Still unsure which DIP switch is right for your design? Search for DIP switch selection guides, comparison charts, and expert reviews to simplify your decision-making process.

DIP Switch Installation and Configuration: Best Practices

Proper installation and configuration are essential for maximizing DIP switch performance and longevity. Here are some industry best practices:

- Follow Manufacturer Instructions: Always refer to datasheets and technical documentation for recommended installation procedures and torque specifications.

- Prevent Electrostatic Discharge (ESD): Handle DIP switches with ESD-safe tools and environments to avoid damaging sensitive components.

- Ensure Secure Mounting: Verify all pins are properly soldered (for through-hole) or reflowed (for surface mount) to prevent intermittent connections.

- Label Switch Positions: Clearly mark switch functions and positions on the PCB or enclosure for user clarity and maintenance efficiency.

- Test All Functions: After installation, test each switch position to confirm correct circuit behavior before final assembly.

- Document Configuration Settings: Maintain configuration logs for future reference, troubleshooting, or device updates.

- Plan for Accessibility: Design enclosures or panels so that DIP switches are easily accessible for field adjustments.

For detailed instructions, search for DIP switch installation videos, step-by-step guides, and troubleshooting FAQs tailored to your specific DIP switch type and manufacturer.

Emerging Trends: DIP Switches in Modern Electronics and IoT

While software-based configuration and digital interfaces are increasingly common, DIP switches remain relevant in many modern applications. In the era of IoT (Internet of Things), Industry 4.0, and smart manufacturing, DIP switches are evolving to offer new features, such as:

- Miniaturization: Ultra-compact DIP switches enable configuration in space-constrained applications, such as wearables and medical devices.

- Improved Reliability: Enhanced contact materials and environmental sealing for use in harsh industrial or outdoor environments.

- Integration with Embedded Systems: DIP switches provide hardware-level device selection and address setting in microcontroller-based designs.

- Hybrid Solutions: Combining DIP switches with digital interfaces for dual-mode configuration and redundancy.

- RoHS and Environmental Compliance: Manufacturers are offering DIP switches with eco-friendly materials and certifications to meet global regulations.

Curious about the future of manual configuration devices? Explore articles on the role of DIP switches in Industry 4.0, IoT deployment strategies, and hybrid device configuration technologies.

Conclusion: Maximizing Value from DIP Switches

The DIP switch was initially developed as an easy way to modify an electronic system's circuits. They permit an individual user or manufacturing-stage configuration modifications. Due to their low cost and simplicity of usage, they continue to be well-suited in various electromechanical devices, even as the development of software switches and user interfaces has decreased their widespread use over time. By comprehending DIP switches and the available variations, these devices can be set up to carry out particular tasks and to even communicate with other compatible devices.

Whether you are designing, integrating, or maintaining electronic systems, understanding DIP switch technology—from SPST to DPDT, toggle to rotary, and everything in between—enables precise, reliable, and cost-effective configuration. Their enduring popularity across industries is a testament to their versatility, ease of use, and adaptability in a rapidly changing technology landscape.

Choosing the Right DIP Switch Supplier: Tips for Procurement and Sourcing

To ensure you have the most productive outcome when purchasing DIP switches from a DIP switch supplier, it is important to compare several companies using our directory of DIP switch companies. Each DIP switch supplier has a business profile page that highlights their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each DIP switch business website using our patented website previewer for a better understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple DIP switch companies with the same form.

When evaluating potential suppliers, consider:

- Product Range and Availability: Does the supplier offer a wide variety of DIP switch types, mounting options, and customization features?

- Quality Assurance: Are their products certified and compliant with industry standards?

- Technical Support: Does the supplier provide datasheets, application notes, and engineering assistance?

- Lead Times and Shipping: Can the supplier meet your project timelines with reliable delivery?

- Pricing and Bulk Discounts: Are competitive pricing and volume discounts available for larger orders?

- Customer Service and Reputation: Check reviews and testimonials from other engineers, buyers, or OEMs.

For more guidance, search for reviews of top DIP switch manufacturers, tips for negotiating with suppliers, and checklists for evaluating electronic component distributors.

Ready to take the next step? Use our comprehensive supplier directory, request quotes, or connect with industry experts to find the perfect DIP switch solution for your application.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

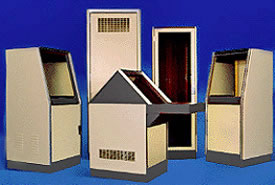

Electronic Connectors Electronic Enclosures

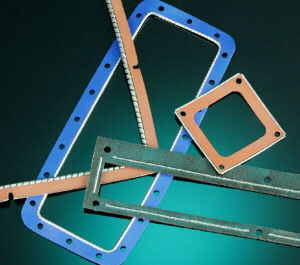

Electronic Enclosures EMI Shielding

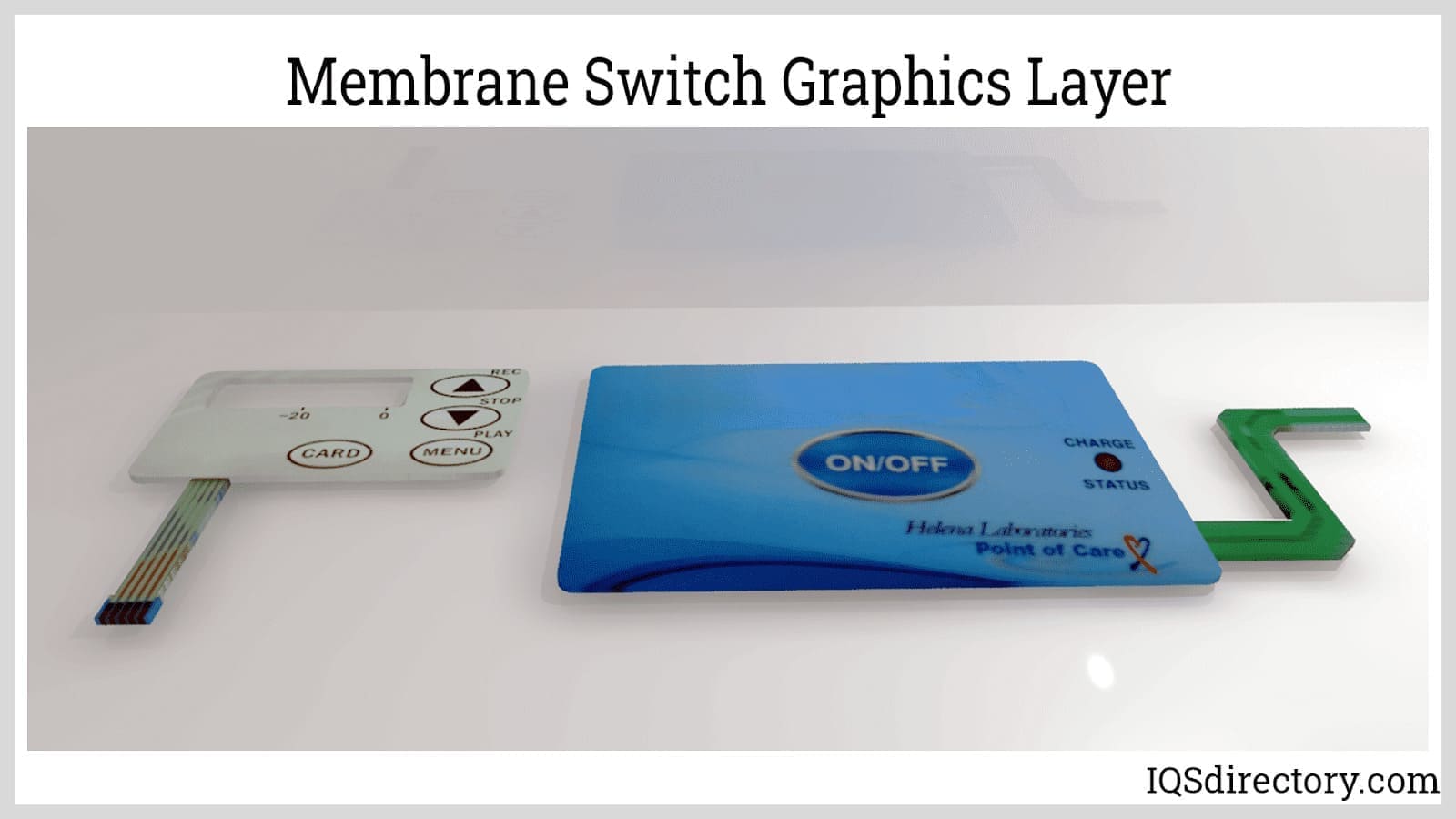

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services