Electric switches are, simply put, components that can open or close an electrical circuit. While small and quite simple, electric switches are an important part of the modern world. People use them constantly, whether to turn on the bathroom light at night or to control machinery in high-risk industrial environments. Read More…

Electro-Mech Components designs and manufactures illuminated pushbutton switches and miniature switches plus multiswitch interlocking assemblies and indicator lights. We have an extensive selection of off-the-shelf pushbutton switches plus industrial-grade switches and are always happy to customize.

Switches Unlimited specializes in new design and replacement of electric switches, industrial components and automation control. They have extensive stocking selection of toggle, miniature, pushbutton, rocker, illuminated switches, relays, proximity, PLC’s and safety controls. Established in 1961, Switches Unlimited represents over 40 leading manufacturers and are a professional leading source...

Known as an industry innovator, NKK® Switches manufactures toggle switches, rocker switches, pushbutton switches, rotary switches & illuminated switches, specializing in miniature & illuminated. Creator of SmartSwitch™ OLED IS programmable graphic & video switches for interactive applications. Our products are available through distributors and excellent customer service is known worldwide.

At MELTRIC, our Switch-Rated plugs and receptacles combine the safety and functionality of a disconnect switch with the convenience of a plug and receptacle into one cost-effective, reliable device. These plugs can be safely connected and disconnected under full load. Since 1982, MELTRIC has been dedicated to ensuring electrical and user safety with every product.

More Electric Switch Manufacturers

Note: Some people refer to electric switches as “circuit breakers.” This comparison stems from the fact that, like a circuit breaker, a switch disrupts and alters, or “breaks,” a circuit when it changes from open to closed. However, electric switches and circuit breakers are not identical. Circuit breakers are specialized devices designed to safely manage electric currents.

History

They were invented some time ago, born out of a need to safely and easily control the flow of electricity. The earliest electric switches were light switches, invented by Thomas Edison, one of the premier inventors of the light bulb. In preparation for the 1880 New Year’s celebration, Edison created a number of electrical components for a light display. Among these components were switches.

Soon after Edison developed his switches, John Henry Holmes, a British engineer, invented the quick break switch. This innovation prevented residue buildup from arcing, enhancing the durability of switches. It also sped up the process by reducing the time needed for two electric contacts to meet within a circuit. By the late 19th century, push button switches had become quite popular.

In 1917, New York-based inventors Morris Goldberg and William J. Newton created the toggle switch, inspired by the quick break switch. Even today, the toggle switch remains a common feature in North American homes, serving as the everyday light switch.

Since the early 20th century, the concept of electronic switches has remained largely unchanged, but the methods we use to control them have evolved significantly. Today, with the advancements in computer technology and modern electronics, we can activate switches remotely, utilize sensors to respond to our environment, send signals, and much more. Looking ahead, these innovations will only continue to expand.

Design

Manufacturers create electronic switches tailored to specifications such as available space, environment, accessibility requirements, and the number of electronic circuits to control.

To design the ideal electric switch for you, manufacturers can customize features like internal configuration, control mechanisms, housings, and size.

For instance, while many switches function independently, manufacturers can also design them to be interconnected, enhancing circuit flexibility. Additionally, they can vary greatly in complexity. Switches range from the simplest types, which need a physical touch between the actuator and conductors, to the most advanced, which rely on sensing a magnetic field or light to operate.

Manufacturers can custom design switches with components hidden in housings made from wood, plastic, or metal for safety or aesthetic purposes, keeping the switch accessible.

They can create switches that are so small they need a miniature tool, like an inkless pen, to be accessed. Conversely, they can design switches that only need a flip of a finger or ones requiring special strength. To explore the various design options, consult with potential suppliers.

Features

Electric switches come in various types, but most share common components like conducting materials, wires, actuators, and terminals.

Switch conducting materials must be corrosion resistant because metal corrosion results in the buildup of insulating oxides that inhibit proper switch function. Conducting materials are also selected for abrasion resistance, mechanical strength, low toxicity, and, ideally, low cost.

Actuators are moving components that function as switches by applying operating force. These devices, housed in protective casings, can take various forms of mechanical linkages. Commonly, actuators appear as toggles, dollies, rockers, or push-buttons.

Terminals are points where electric conductors connect to external circuits. They can be standalone wire ends or equipped with fasteners or connectors.

How They Work

Electric switches operate by either permitting or halting the flow of electric current within a circuit, following the principle of open or closed circuits. When a switch is in the “closed” position, it completes the circuit, creating a continuous pathway for electricity to travel. This connection of the switch’s terminals allows the current to flow freely, ensuring the load connected to the circuit receives power. In this state, the switch is actively conducting electricity.

Conversely, when switches are in the “open” position, they break the circuits, disconnecting the terminals from each other. As a result, the flow of electric current is interrupted, and the loads are deprived of power. In this state, the switches act as insulators, preventing electricity from passing through.

The actuators of the switch, such as toggles, buttons, or levers, are used to change the switches’ states. When we move the actuators to the “on” positions, the switches close, completing the circuits and allowing current to flow. Conversely, when we move the actuators to the “off” positions, the switches open, interrupting the circuits, and stopping the current flow.

Our ability to open and close circuits is essential for controlling electrical devices and systems. We use electric switches extensively in many applications, from simple household lighting switches to complex industrial control systems. They offer us a convenient and safe way to regulate the flow of electricity and power various electrical devices.

Types

A major variable in all electrical switches is the type of actuator, or how they are controlled. Based on this, we can categorize switches into groups, including those that are physically controlled, mechanically controlled, and electronically controlled.

Mechanically Controlled Types

Toggle switches control the flow of electrical power to devices by shifting between two or more positions. The simplest toggle switches alternate between off and on, while more complex versions may offer multiple positions. Typically, a toggle switch consists of a lever or handle used to change positions, and an internal spring that ensures the lever stays securely in place at each setting.

These switches are versatile, suitable for controlling household lights, managing industrial machinery, making quick connections and disconnections, and fast switching. They’re particularly useful when control devices are mounted in close proximity. Many of these switches can handle switching 250 VAC at currents around 1 amp.

Push button switches feature actuators in the form of flush, recessed, or raised buttons. These switches provide two-position control, activated by pressing any of the button types. When we push the button “in,” it completes a connection in the internal circuit, turning on the connected device. A spring inside the switch pushes the button back to its “out,” or off, position, breaking the circuit and turning off the device once we release the button. This mechanism is particularly useful for applications that require only brief connections or momentary electrical inputs.

Slide switches interrupt the flow of current to “break” electrical circuits by moving from position to position in a straight line. Featuring sliding actuators, slide switches offer at least two positions: “on” and “off.”

Waterproof switches are crafted to withstand water’s harmful effects, along with other challenges like shock, salt, corrosion, and vibrations. These switches are securely encased in watertight housing to ensure their protection.

Rotary switches operate easily with a rotating control knob. They are commonly used in applications needing more options than just on and off, as they can be turned to multiple positions. This capability allows one point to connect to various points within an electronic circuit. These switches come in various forms, including versions with three levels all connected to a common shaft.

Rocker switches are those switches that lift at one end when we press down the other end.

DIP (dual in-line package) switches are manually operated and can function as rocker, slide, or rotary switches. These switches are commonly found in devices like remote controls and garage door openers. The term “DIP switches” can refer to a single switch or small groups of several switches. In such cases, the device housing these switches is often called a switch panel.

Speed switches monitor the rotational motion and speed of shafts or other rotating components. Once the speed of these components reaches a predetermined point, the control circuit is activated. These switches can track shaft speed using various methods, such as centrifugal weight mechanisms, magnetic pick-up mechanisms, or optical mechanisms.

Keylock switches, a subtype of rotary switches, are commonly used in security applications. To operate them, we need to insert a key and turn it to the appropriate position, which could be any stop within a complete circle. These switches may function in just one position or offer various functions accessible at different positions.

Limit switches are devices that prevent objects from moving beyond a predetermined point.

Electronically Controlled Types

Switch relays are electronically controlled switches.

Signal switches absorb information from the surroundings to determine how to adjust their circuits. They modify circuits using electronic inputs. Numerous products depend on signal switches. Examples of these products include thermostats, security lights, driving indicators and lights, medical equipment, and food processing equipment.

Semiconductor transistors are the most prevalent type of electric switches. We find them in a wide range of computing components.

Remote electrical switches control circuits from a distance, allowing us to activate or deactivate them without direct physical contact. These switches are commonly found inside remote controls.

Proximity switches activate when they detect an object approaching. Commonly used in machinery, these switches utilize magnetic and high-frequency electromagnetic fields to sense metallic components nearing the switch location, causing the switch to close. This is achieved by energizing a coil of wire with a high-frequency current, which is then monitored. When a metallic object or component approaches, the current in the coil increases, triggering the switch. However, not all proximity switches operate this way. Some use an optical mechanism with photocells that monitor incoming light, and the switch is triggered when the incident light is blocked or interrupted.

Temperature switches employ a strip made of bimetallic materials, consisting of two metals with distinct thermal properties bonded together. These metals have different coefficients of thermal expansion, causing the strip to bend when heated or cooled. This bending action serves as a contact mechanism. By orienting the strip properly, it can be made to bend and connect with the circuit when heated and bend away from the circuit when cooled, or the other way around.

Other

Single-pole switches, designed for general use, feature two actuator positions: “on” and “off.” They can be classified as either single throw (SPST switches) or double throw (SPDT switches), indicating the number of terminals that complete the circuit. Additionally, single-pole switches can be adapted into three-way or four-way switches.

Double pole switches function with two actuators that can either connect or disconnect from a circuit. They are typically used for devices with multiple mechanical components operating simultaneously. These switches also enable the switching of appliances between 240-volt circuits and other circuits with different current levels. Depending on the number of conducting positions their actuators can adopt, they can be classified as either single-throw (DPST) or double-throw (DPDT) switches.

Joystick switches, unlike toggle switches that are governed by a single lever, feature a lever that can move across multiple axes. This multi-directional movement provides a greater range of control options. Typically, these switches have multiple contact mechanisms that respond to both the direction and the extent to which the lever is pushed. They are frequently used in motion control devices, offering a range of control from coarse to fine adjustments.

Switch panels, designed to manage multiple electronic circuits, can include a mix of single pole and double pole switches, or various other types. The internal mechanisms are enclosed within a housing typically crafted from wood, plastic, or metal, while the switches themselves are affixed to the panel’s front.

Air switches use air as insulation between open contacts, causing the circuit to be interrupted midair.

Modular switches feature multiple ports, providing a variety of connection possibilities. They are available in an array of shapes, sizes, and colors to match diverse needs and preferences.

Load break switches are switches that disconnect, or break, and disconnect at preset currents. They can work with or without fuses. Fuses are safety wires that break and melt if the circuit exceeds safe operation levels.

Transfer switches are built to alternate loads between two power sources. They can be either manually operated or automated, with automatic transfer switches handling the switching process on their own.

Applications

Electric switches serve a wide range of purposes in both everyday life and specialized industries. At home, we often use them to manage lighting and operate appliances like fans and kitchen gadgets. In the realm of electronics, switches play a vital role in device operation, from touch-sensitive controls on smartphones to physical buttons on laptops. Industrial settings depend on electric switches to control heavy machinery, ensuring that equipment runs smoothly and safely, which is crucial for both worker safety and production efficiency. In the automotive industry, electric switches are essential for managing functions like headlights, windows, mirrors, and dashboard controls, enhancing both vehicle safety and convenience. Electronic circuits, especially in digital systems, use switches such as transistors for data processing and logic operations. Telecommunication systems rely on electric switches in telephone exchanges to connect callers seamlessly. Additionally, electric switches are vital in security systems, medical equipment, power distribution, transmission, and aerospace, playing a key role in the operation, safety, and control of these complex systems. In essence, electric switches are fundamental components that provide control and convenience across a broad spectrum of applications, making them indispensable in modern technology and infrastructure.

Choosing the Right Manufacturer

To secure top-notch products, it’s crucial to partner with a manufacturer who truly grasps your needs and provides high-quality electric switch services at a fair price. Explore the electric switch manufacturers listed on this page to find potential partners. As you review them, keep your application specifications and requirements in mind, such as delivery schedules, budget constraints, and certification standards. Select three or four manufacturers to engage with further. Initiate conversations with each, delve into your specific application, and evaluate their responses to determine which supplier best meets your needs.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

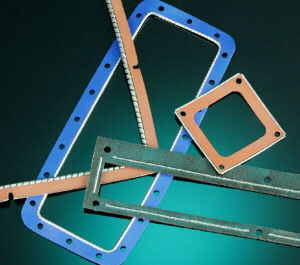

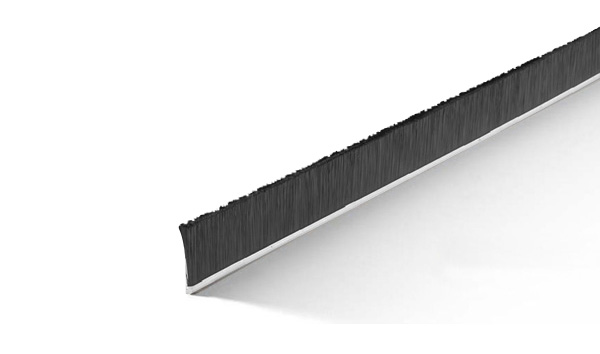

Electronic Enclosures EMI Shielding

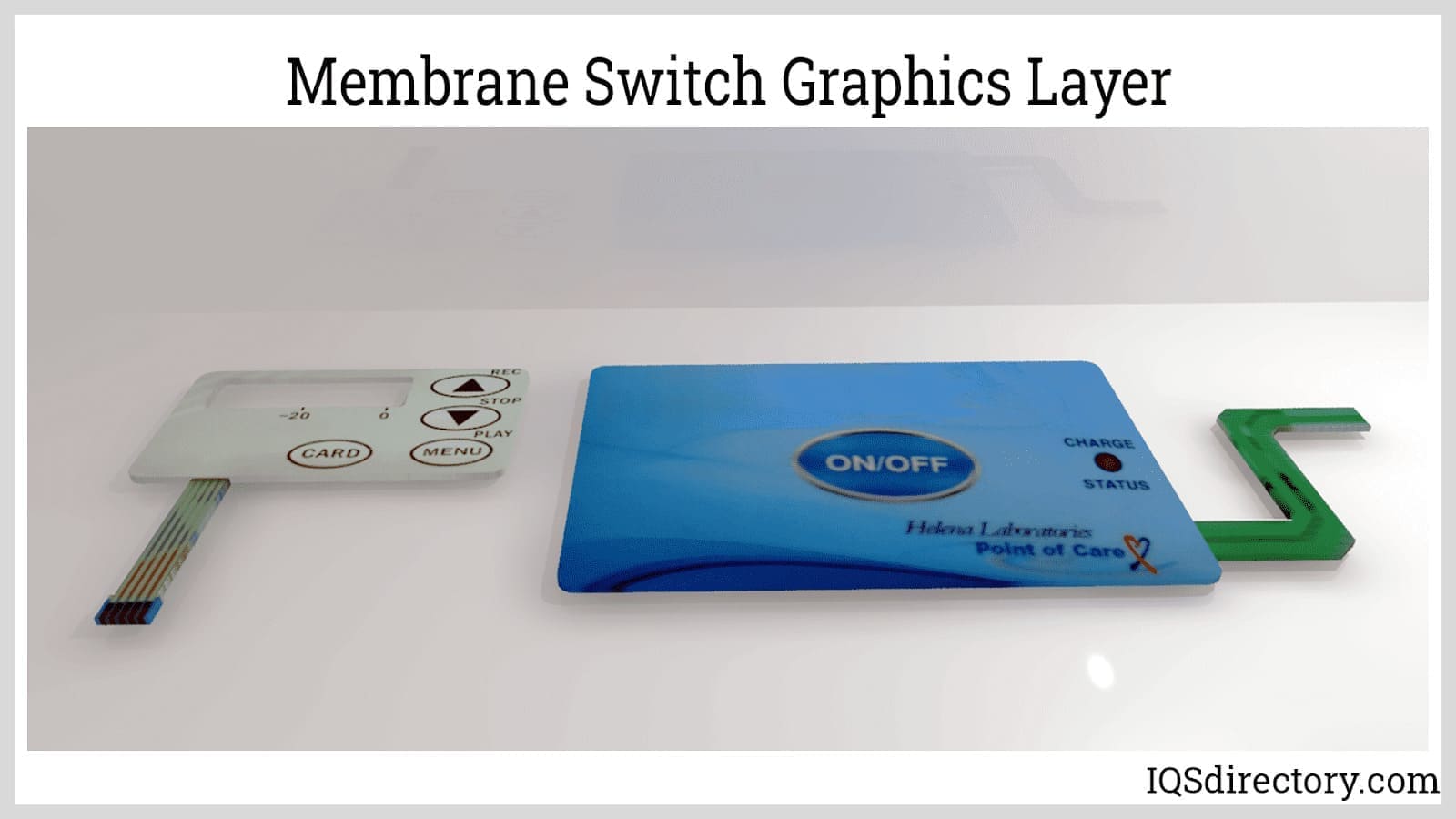

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services