Rocker switches are electrical switches with an operating button that users can press on either end to connect or disconnect an electrical circuit. The primary power sources for electrical equipment are frequently employed as ON/OFF switches. They come in various configurations: three-position, momentary, maintained, and two-position on/off. Read More…

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of electric switches, membrane switches, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes.

At ALMAX, we specialize in the design and manufacturing of electronic switches that merge precision engineering with customizable interface solutions. Our products are engineered to serve a wide range of industries, from medical device manufacturers to aerospace, industrial controls, and consumer electronics.

At CSI Keyboards, Inc., we have built our reputation around engineering electric switches that combine precision, reliability, and adaptability for a wide range of applications. Our switches are designed to meet the demands of industries where durability and accuracy are critical, from medical devices and industrial equipment to commercial electronics and beyond.

ABB is a manufacturer of low-voltage electrical switches. We offer relaying products, automation products—limit switches, rotary switches, toggle switches, disconnect switches, cam switches and safety switches for construction, process industries, industrial and OEM markets.

At Schneider Electric, we design and manufacture advanced electric switches that bring efficiency, reliability, and innovation to power control and automation systems worldwide. Our switches are engineered to meet the diverse needs of industrial, commercial, and residential environments, offering precise performance, safety, and durability.

At Powell® Electronics, we are dedicated to providing our customers with the best products and services possible. We understand that each customer has unique requirements, and we are committed to meeting those needs with high-quality products and exceptional customer service. Whether you need a standard electronic component or a custom-designed solution, we have the expertise and experience to...

Electric switches for industrial, residential and commercial uses are manufactured by Leviton Manufacturing Company. We offer switches with Amp ratings of 15, 20 and 30; they can include motor starter, lighted handle or pilot light, single-pole, double-pole, three-way and four-way.

More Rocker Switch Manufacturers

Types of Rocker Switches

Rocker switches are versatile, user-friendly electrical switches that are widely used across various industries and applications. Selecting the right rocker switch configuration is essential for ensuring safety, efficiency, and reliable electrical control within your system. Understanding the available types, their functions, and their ideal use cases can help you make informed purchase decisions when choosing rocker switches for your projects.

3-Position Configuration

Three-position rocker switches, often referred to as 3-way rocker switches, are designed to enable flexible control over electrical circuits. They feature three distinct electrical connections:

- The input power is delivered to the rocker switch at the pin.

- The device the switch will activate is linked to the pin.

- The switch is connected to the ground or is left unconnected at the pin.

This configuration allows users to toggle between two circuits or states, or to have a central 'off' or neutral position. 3-position rocker switches are commonly used in applications where an operator may need to control a device in two directions, such as in motorized window actuators or adjustable equipment controls.

Momentary Rocker Switch Configuration

Momentary rocker switches differ from standard maintained switches by only activating an electrical circuit while being pressed. When users press a standard rocker switch, it latches into that position and stays there until it is moved the other way. However, a momentary switch only activates when it is depressed and goes back to its normal setting when it is not. Typical applications include horn buttons, reset switches, or any device where a temporary electrical connection is needed for safe operation.

Maintained Rocker Switch Configuration

Maintained rocker switches have three positions—UP, DOWN, and sustaining—and operate similarly to an automobile window switch. This rocker switch style implies that internal limit switches will disconnect the power to the actuator once it has completed its full stroke. When the user presses the switch, it remains in that position. One only needs to depress the switch's down button to bring the actuator back. Maintained rocker switches are ideal for applications such as power windows, seat adjustments, and systems that require a stable, hands-free operation.

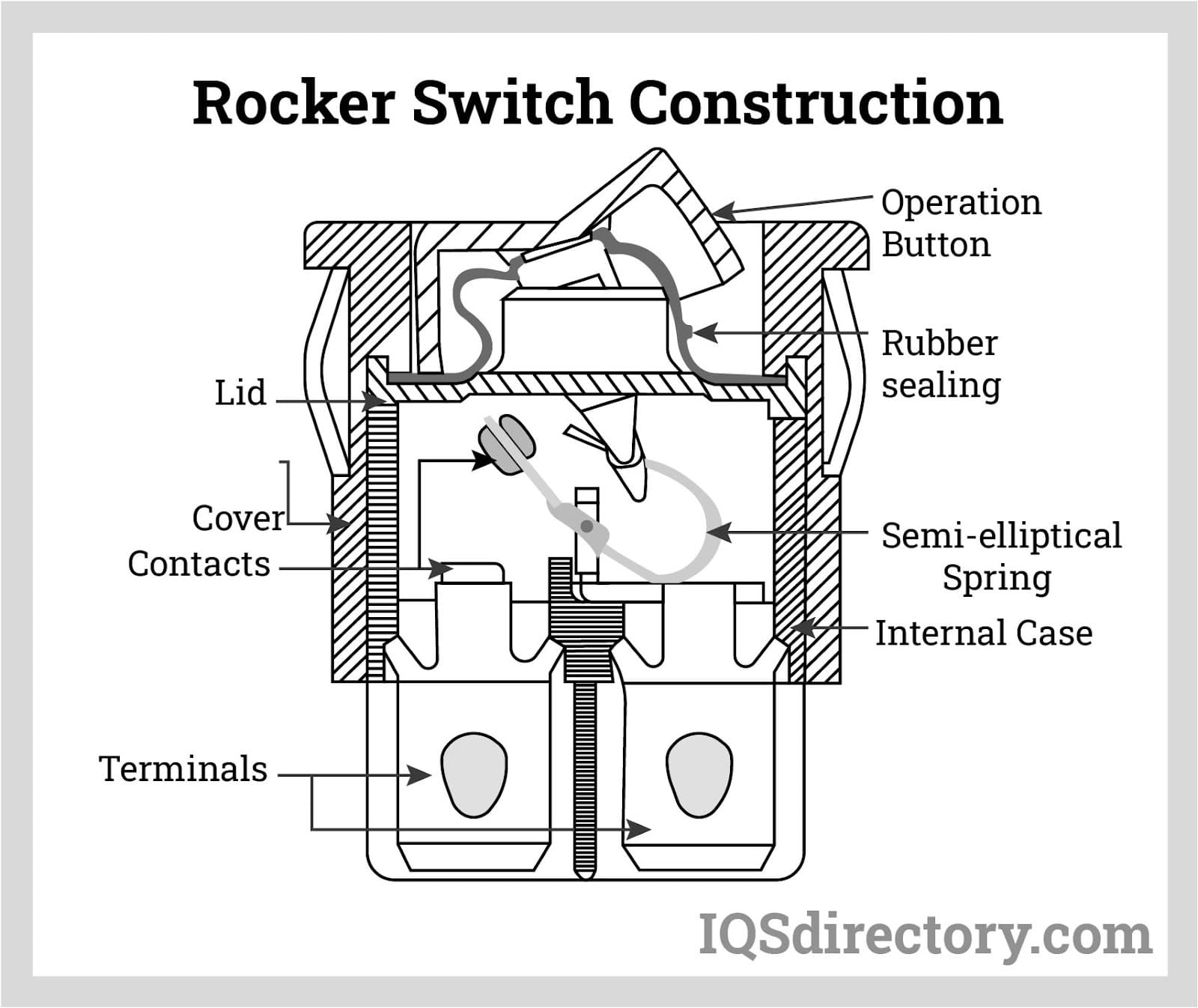

Rocker Switch Components

Rocker switches are complex devices consisting of various yet critical parts. Understanding these components is essential when evaluating rocker switch quality, durability, and suitability for different electrical and electronic applications.

Operation Button

The operation button, or actuator, is the interface that users manually press or toggle to change the state of the switch. Many modern rocker switches feature illuminated buttons, tactile feedback, or labeling to indicate ON/OFF status, which improves usability and safety in low-light or high-vibration environments. Choosing the right actuator style can help optimize your control panel's ergonomics and accessibility.

Rubber Sealing

Rubber sealing is a rubber component used to seal the switch and protect it from moisture, dust, and other environmental contaminants. Weatherproof and waterproof rocker switches are essential in automotive, marine, and outdoor equipment to ensure long-term reliability, even in harsh conditions. If your application is exposed to the elements, consider IP-rated sealed rocker switches for maximum protection.

Spring and Contacts

The spring inside the switch is made by a leaf spring that has a contact attached at its end. When the switch is turned ON, the spring immediately advances its contact to another, fixed contact within the rocker switch unit. This connection of contacts provides electrical flow. However, this connection is broken as the spring retracts when switched back to the OFF position. High-quality contact materials such as silver or gold plating increase conductivity and reduce wear, ensuring a long service life and consistent performance in demanding industrial applications.

Cover

The switch's cover wraps around the interior casing to safeguard the rubber sealing and hold it in place. It also serves as a barrier against accidental activation and enhances the overall safety of the electrical circuit. Durable covers made from thermoplastics or polycarbonate materials offer additional impact and chemical resistance, making them suitable for rugged environments.

Terminals

Terminals must fix one of the contacts to ensure connection. This contact is linked to one of the terminal ends. Common terminal types include quick-connect, solder lug, screw, and PC (printed circuit) board pins, each offering unique advantages for different installation requirements. Selecting the right terminal configuration ensures reliable integration into your wiring harness or PCB assembly.

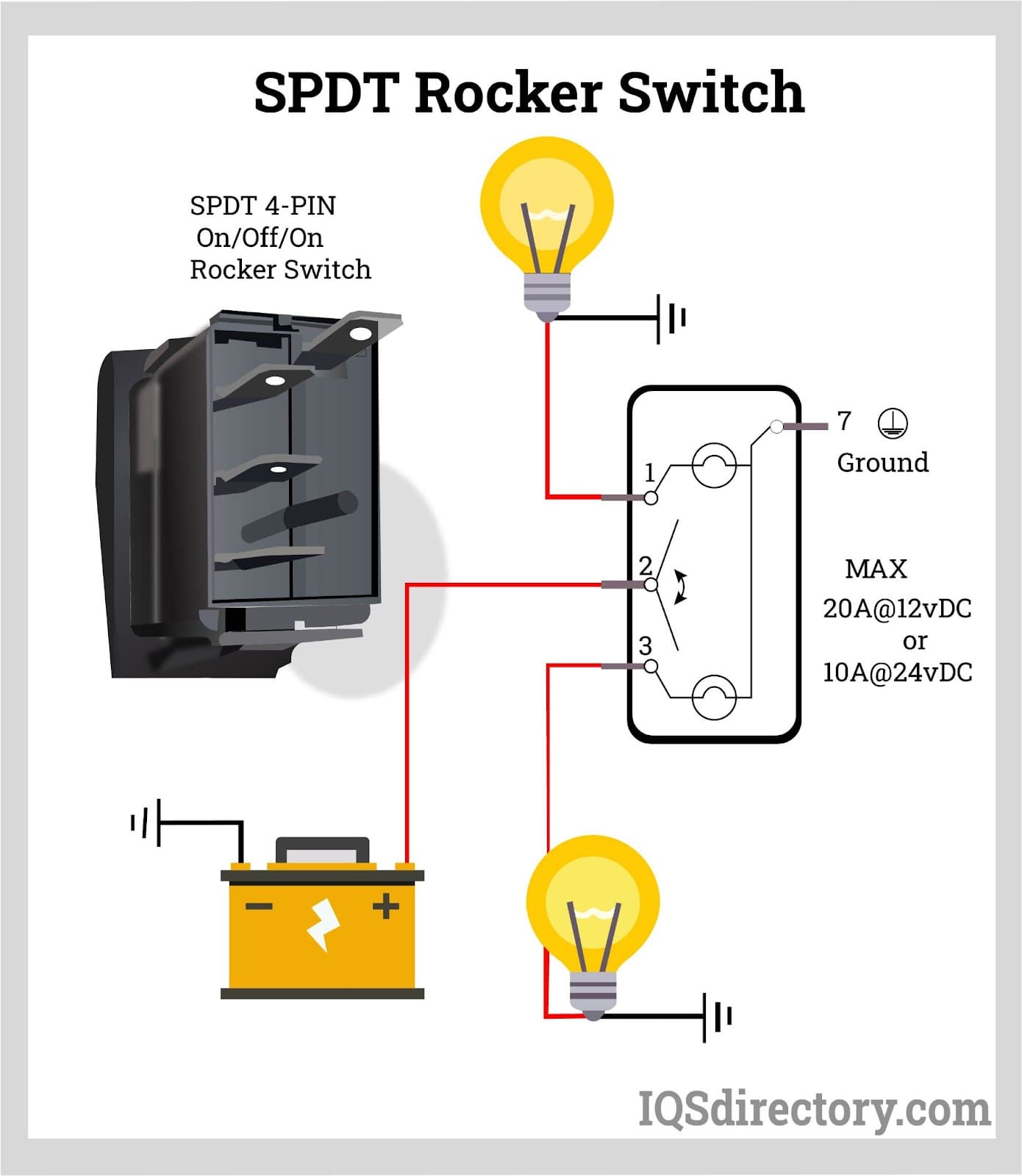

Configurations for Pole and Throw

Rocker switches are categorized by their pole and throw configuration, which defines how many circuits can be controlled and how many output paths are available. Understanding these options is crucial when designing control panels, machinery, or consumer electronics.

One conductor in a single branch circuit can be connected or disconnected using SPST (single-pole, single-throw) rocker switches. This sort of switch is referred to as a single-pole, single-throw switch and normally has two terminals. SPST switches are commonly used for simple ON/OFF control in lighting, power strips, and other basic electrical devices.

A single conductor can be connected to one of two additional single conductors using SPDT (single-pole, double-throw) rocker switches. Typically having three terminals, these switches are frequently used in pairs. Three-way switches are another name for SPDT switches. They are ideal for applications requiring alternate control, such as switching between two circuits or selecting between power sources.

Two source terminals are frequently connected to the corresponding output terminals using a double-pole, single-throw (DPST) switch, which has four terminals (but never to each other). DPST rocker switches make or break the connection between two circuit conductors in a single branch circuit. Normally, they have four terminals. These are often used for isolating both live and neutral connections in AC mains circuits for added safety.

Two wires can be connected to two different circuits using DPDT (double-pole, double-throw) rocker switches. They typically come in versions with momentary and sustained contacts and have six terminals. In their (normal) condition, the contacts of a normally open (NO) rocker switch are either open or unconnected. Conversely, contacts in a normally closed (NC) rocker switch are closed or connected when they are in their (normal) condition. DPDT switches are ideal for reversing polarity in motors, switching between multiple devices, or complex control circuits.

Switch Functions

Rocker switches are available in multiple functional configurations to suit a wide variety of electrical control needs:

- Momentary ON: When the rocker switch is in the typical, open (NO) position, it depicts connections that break the circuit. This function is often used for push-to-activate devices such as buzzers, alarms, or motor starters.

- Momentary OFF: When the rocker switch is in the typical, closed (NC) position, describes connections that create a circuit. This is suited for safety interlocks or circuits that should remain energized except during manual interruption.

- Momentary center-NEUTRAL: Rocker switches with three positions feature an OFF or NEUTRAL function in the middle, offering flexible control for bidirectional motors or dual-mode devices.

When choosing a rocker switch, consider the intended function (ON/OFF, momentary, maintained, illuminated, etc.) and ensure compatibility with your application requirements.

Specifications for Rocker Switches

As previously discussed, there are various types of rocker switches with different methods and functions of operation and feature numerous components. Below, we list a variety of other factors to consider when choosing an appropriate rocker switch for one's application. These parameters are critical for ensuring safety, compatibility, and longevity in both commercial and industrial settings.

- Dimensions, electrical ratings, terminal types, materials, and functions are among the crucial parameters to consider for rocker switches.

- Electrical requirements (voltage and current ratings)

- Current rating ceiling (maximum amperage supported)

- Maximum AC voltage (e.g., 120V, 240V)

- Maximum DC voltage (e.g., 12V, 24V, 48V DC)

- Maximum power rating (wattage capacity)

- Expected mechanical life (number of cycles)

- Environmental sealing (IP rating, waterproof or dustproof capabilities)

- Panel mounting dimensions and cutout requirements

- Panel width and thickness compatibility

- Terminal class (quick-connect, solder lug, PC pins, screw type)

- Feed-through design and wiring style

- Cable leads and wire gauge compatibility

- Terminals soldered (permanent installation needs)

- Nut terminals (for secure, vibration-resistant mounting)

- Blade or quick-connect terminals (for fast, tool-less installation)

- Surface-mount engineering (SMT) for PCB integration

- Slender PC pins, straight PC pins, or PC side pins (for various board layouts)

Are you wondering how to choose the right rocker switch for your specific project? Consider your circuit's voltage and current requirements, physical size constraints, environmental conditions, and the desired user interface. For more details, see our rocker switch selection guide.

Resources Used in the Construction of Rocker Switches

Most rocker switch bases and actuators are constructed from metal, thermoplastic, or plastic materials. The choice of material directly impacts the switch's durability, electrical insulation properties, resistance to chemicals, and resistance to mechanical wear. High-grade thermoplastics are often selected for their lightweight, flame-retardant, and insulation properties, while metals may be used for high-strength industrial switches.

The Uses of Rocker Switches

Rocker switches are ubiquitous in modern electrical systems, offering reliable and intuitive control in a broad spectrum of environments. Their applications span from consumer electronics to heavy industrial equipment. Below are some of the most common and specialized uses for rocker switches:

- Instrumentation front portions (shut-off switches)

- Electrical apparatus (power supplies, power outlet strips, battery chargers)

- Appliances for the home (small and large, vacuum cleaners, food equipment)

- Computers and related devices (servers, network hubs, routers)

- Audiovisual and telecommunications equipment

- Industrial machinery (control panels, handling and packing machines, HVAC units, shop vacs)

- Small apparatus (handheld devices, electric tools, office equipment)

- Emergency lighting, generators, and lighting fixtures

- Off-road automobiles, automotive dashboards, and marine vessels

- Medical devices (surgical tools, hospital beds, diagnostic equipment)

- Laboratory instruments and scientific equipment

- Special-use electro-mechanical switches certified under EIA-520D000

- Naval Electronic Systems Command, Department of the Navy, has approved this specification sheet, which is available for use by all Department of Defense Departments and Agencies.

Benefits of Rocker Switches: Why Choose Rocker Switches?

Rocker switches are a preferred solution for electrical circuit control due to their unique combination of advantages. Here’s why engineers, manufacturers, and hobbyists continue to choose rocker switches for a wide range of applications:

- Intuitive operation: Easy to use with a clear tactile response, reducing the risk of user error.

- Compact design: Fits into tight spaces and crowded control panels, maximizing real estate.

- Durability: Designed for high cycle counts and harsh environments, particularly when sealed or encapsulated.

- Wide electrical ratings: Available for both low-voltage DC circuits and high-voltage AC applications.

- Customizability: Offered in a range of colors, legends, illumination options, and actuator shapes for user guidance and branding.

- Cost-effective: Simple construction and mass production make rocker switches affordable, even for large-scale installations.

- Safety features: Models available with mechanical interlocks, lockouts, and illuminated indicators to enhance system safety and compliance.

- Versatility: Suitable for printed circuit boards, panel mounting, and through-hole applications.

- Environmentally robust: Available in waterproof, dustproof, and corrosion-resistant versions for outdoor and marine use.

Why do so many engineers prefer rocker switches over toggle or pushbutton switches? The answer lies in their reliability, ergonomic design, and adaptability for both simple and complex circuits.

Key Decision Factors When Buying Rocker Switches

When researching and evaluating rocker switches for purchase, consider the following decision factors to ensure optimal performance, safety, and value:

- Electrical ratings: Ensure the switch supports the voltage and current requirements of your application.

- Environmental protection: Choose IP-rated or sealed models for exposure to moisture, dust, or chemicals.

- Mounting and installation: Verify panel cutout dimensions, terminal compatibility, and installation tools required.

- Compliance and certifications: Look for UL, CE, RoHS, or military specifications for quality assurance and regulatory compliance.

- Life expectancy: Select switches rated for your application's expected number of actuations.

- Customization options: Assess the need for legends, illumination, or special actuator shapes for user interface clarity.

- Lead times and availability: Source from suppliers that can meet your timeline and provide technical support.

- Cost considerations: Balance unit price with features, durability, and warranty to maximize ROI.

Choosing the Right Rocker Switch Supplier

To make sure you have the most positive outcome when purchasing rocker switches from a rocker switch supplier, it is important to compare several companies using our directory of rocker switch suppliers. Each rocker switch supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each rocker switch business website using our proprietary website previewer for a better idea of what each company specializes in. Then, use our simple RFQ form to contact multiple rocker switch businesses with the same form.

When evaluating suppliers, consider their inventory selection, technical support, customization capabilities, compliance with industry standards, and shipping reliability. Top-tier suppliers offer extensive product catalogs, competitive pricing, and value-added services such as private labeling, kitting, and design assistance.

Ready to find the best supplier for your needs? Start by exploring our rocker switch supplier directory and request quotes from multiple vendors to compare pricing, availability, and service levels.

Frequently Asked Questions About Rocker Switches

- What is the difference between a maintained and a momentary rocker switch? Maintained switches stay in their set position until manually changed, while momentary switches return to their default state when released. Each is better suited for specific types of control circuits—see our types of rocker switches page for more details.

- Can rocker switches be used for both AC and DC circuits? Yes, but you must select a switch rated for your application's voltage and current. Always check manufacturer specifications for AC/DC compatibility.

- Which industries use rocker switches most? Rocker switches are widely used in automotive, marine, industrial automation, home appliances, medical devices, and consumer electronics.

- Are illuminated rocker switches available? Yes, illuminated rocker switches come in various colors and designs, offering visual feedback for status indication or night-time operation.

- What environmental ratings are available for rocker switches? Many models are designed to meet IP65, IP67, or higher ratings for water and dust resistance. Consult product datasheets or our waterproof rocker switch overview for more information.

Get Expert Help With Your Rocker Switch Project

Whether you're designing a new product, upgrading an existing system, or sourcing components for repair, our team can help you identify the perfect rocker switch for your specific requirements. From technical specifications to custom solutions, take advantage of our expert support services and get answers to your toughest questions.

Still have questions? Ask us:

- Which rocker switch is best for my application?

- How do I ensure compatibility with my existing wiring or PCB?

- What certifications should I look for in safety-critical environments?

- How do I find the best price for bulk rocker switch orders?

Contact us today to discuss your requirements and get a customized solution designed for your industry and application.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

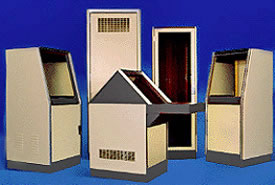

Electronic Connectors Electronic Enclosures

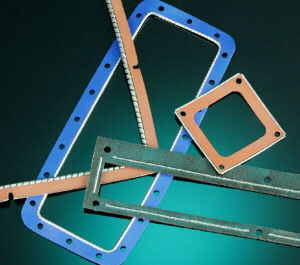

Electronic Enclosures EMI Shielding

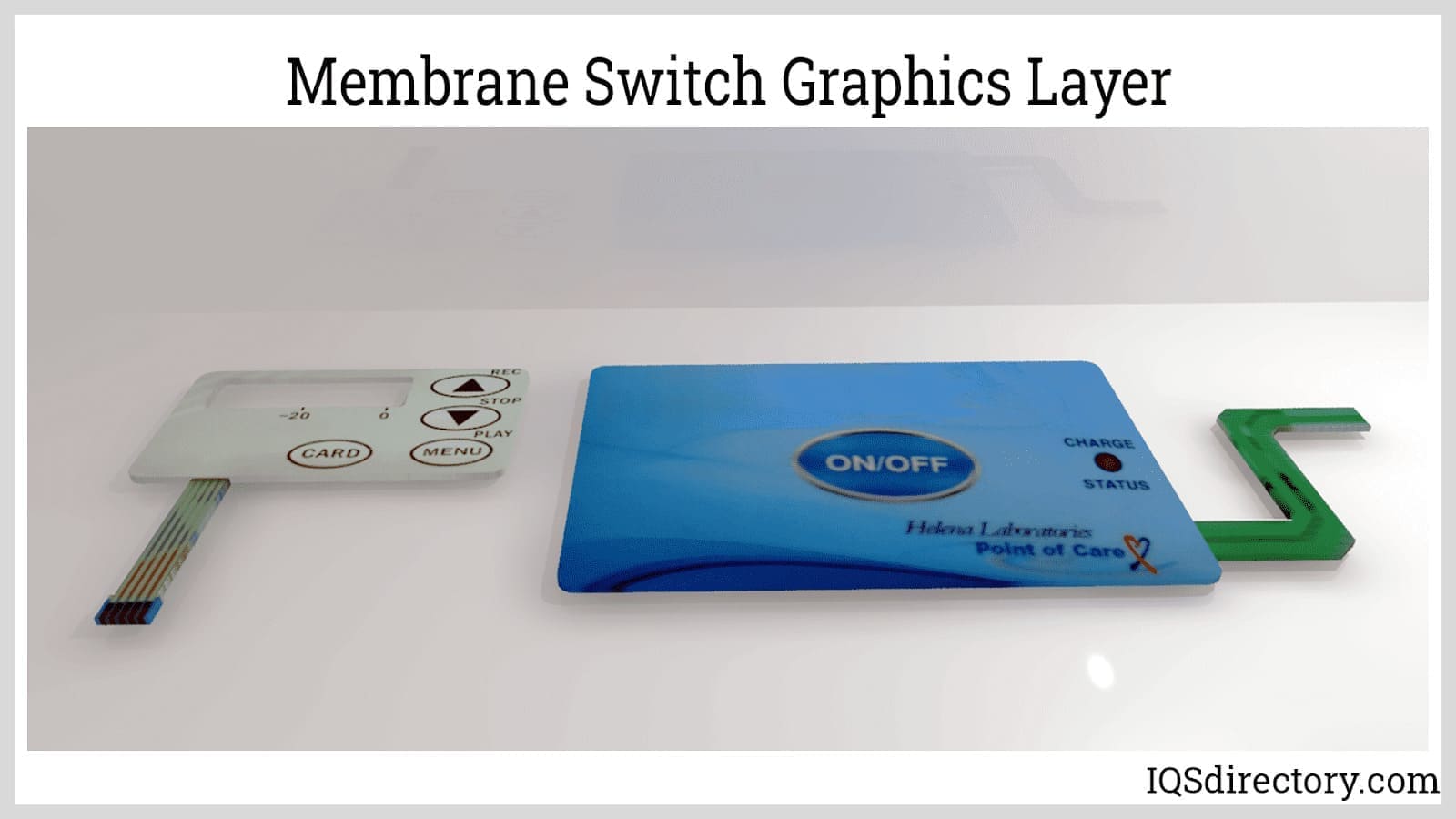

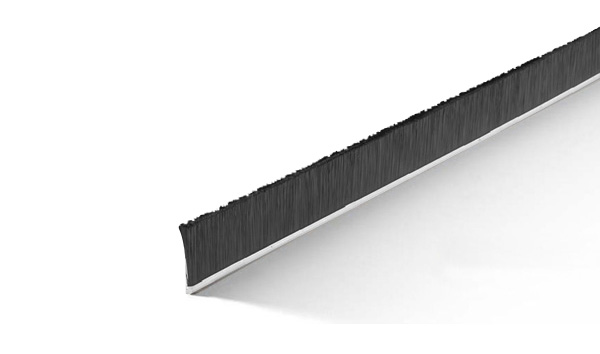

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services