Rocker switches are electrical switches with an operating button that users can press on either end to connect or disconnect an electrical circuit. The primary power sources for electrical equipment are frequently employed as ON/OFF switches. They come in various configurations: three-position, momentary, maintained, and two-position on/off. Read More…

Electro-Mech Components designs and manufactures illuminated pushbutton switches and miniature switches plus multiswitch interlocking assemblies and indicator lights. We have an extensive selection of off-the-shelf pushbutton switches plus industrial-grade switches and are always happy to customize.

Switches Unlimited specializes in new design and replacement of electric switches, industrial components and automation control. They have extensive stocking selection of toggle, miniature, pushbutton, rocker, illuminated switches, relays, proximity, PLC’s and safety controls. Established in 1961, Switches Unlimited represents over 40 leading manufacturers and are a professional leading source...

Known as an industry innovator, NKK® Switches manufactures toggle switches, rocker switches, pushbutton switches, rotary switches & illuminated switches, specializing in miniature & illuminated. Creator of SmartSwitch™ OLED IS programmable graphic & video switches for interactive applications. Our products are available through distributors and excellent customer service is known worldwide.

At MELTRIC, our Switch-Rated plugs and receptacles combine the safety and functionality of a disconnect switch with the convenience of a plug and receptacle into one cost-effective, reliable device. These plugs can be safely connected and disconnected under full load. Since 1982, MELTRIC has been dedicated to ensuring electrical and user safety with every product.

More Rocker Switch Manufacturers

Types of Rocker Switches

3-Position Configuration

There are three electrical connections on 3-way rocker switches:

- The input power is delivered to the rocker switch at the pin.

- The device the switch will activate is linked to the pin.

- The switch is connected to the ground or is left unconnected at the pin.

Momentary Rocker Switch Configuration

When users press a standard rocker switch, it latches into that position and stays there until it is moved the other way. However, a momentary switch only activates when it is depressed and goes back to its normal setting when it is not.

Maintained Rocker Switch Configuration

Maintained rocker switches have three positions- UP, DOWN, and sustaining- and operate similarly to an automobile window switch. This rocker switch style implies that internal limit switches will disconnect the power to the actuator once it has completed its full stroke. When the user presses the switch, it remains in that position. One only needs to depress the switch's down button to bring the actuator back.

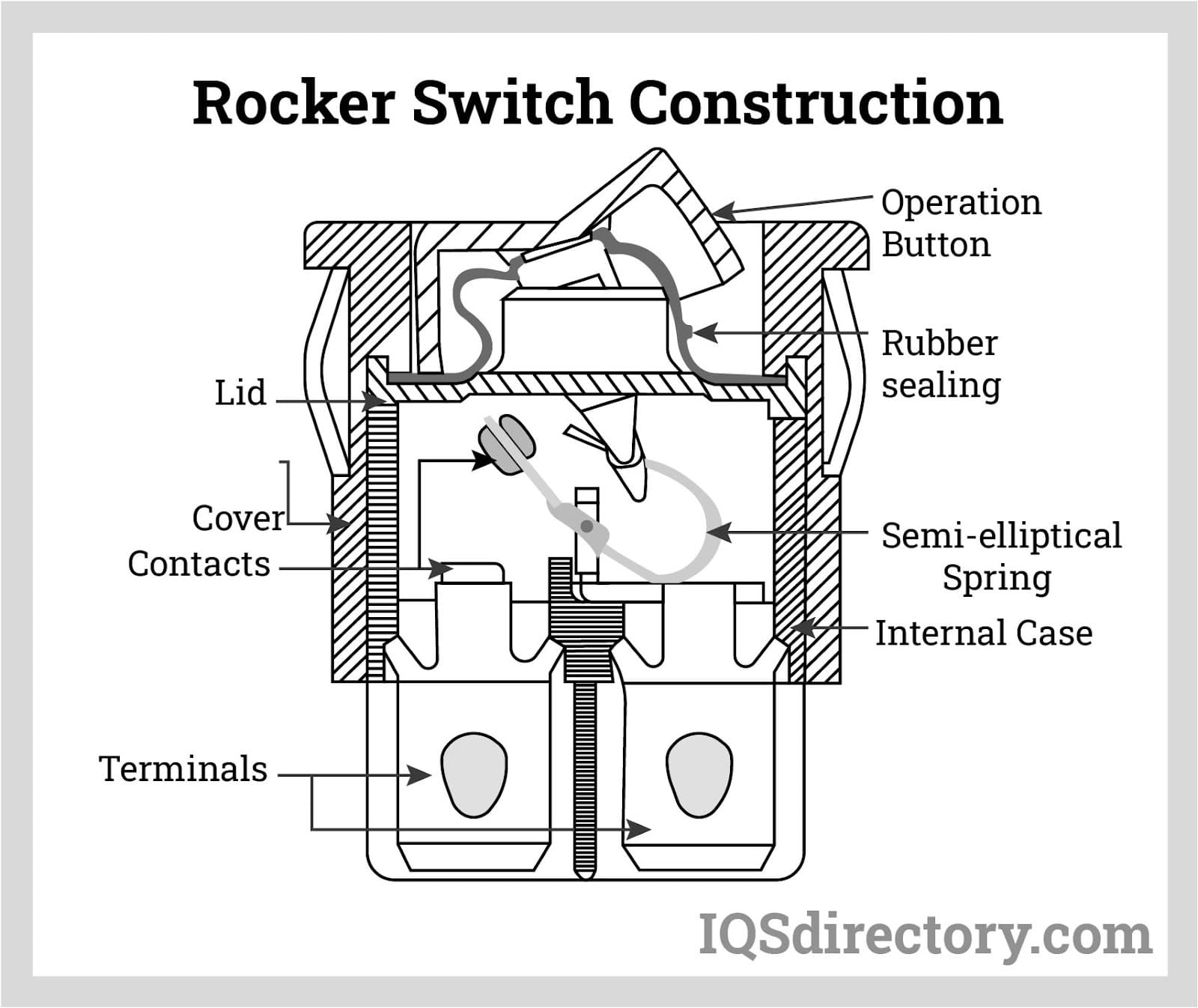

Rocker Switch Components:

Rocker switches are complex devices consisting of various yet critical parts. Below, we discuss many of these components.

Operation Button

Users must push the operation button to operate the functions manually. Certain switches indicate the ON/OFF condition on the button.

Rubber Sealing

Rubber sealing is a rubber component used to seal the switch and protect it from moisture.

Spring and Contacts

The spring inside the switch is made by a leaf spring that has a contact attached at its end. When the switch is turned ON, the spring immediately advances its contact to another, fixed contact within the rocker switch unit. This connection of contacts provides electrical flow. However, this connection is broken as the spring retracts when switched back to the OFF position.

Cover

The switch's cover wraps around the interior casing to safeguard the rubber sealing and hold it in place.

Terminals

Terminals must fix one of the contacts to ensure connection. This contact is linked to one of the terminal ends.

Configurations for Pole and Throw:

One conductor in a single branch circuit can be connected or disconnected using SPST rocker switches. This sort of switch is referred to as a single-pole, single-throw switch and normally has two terminals.

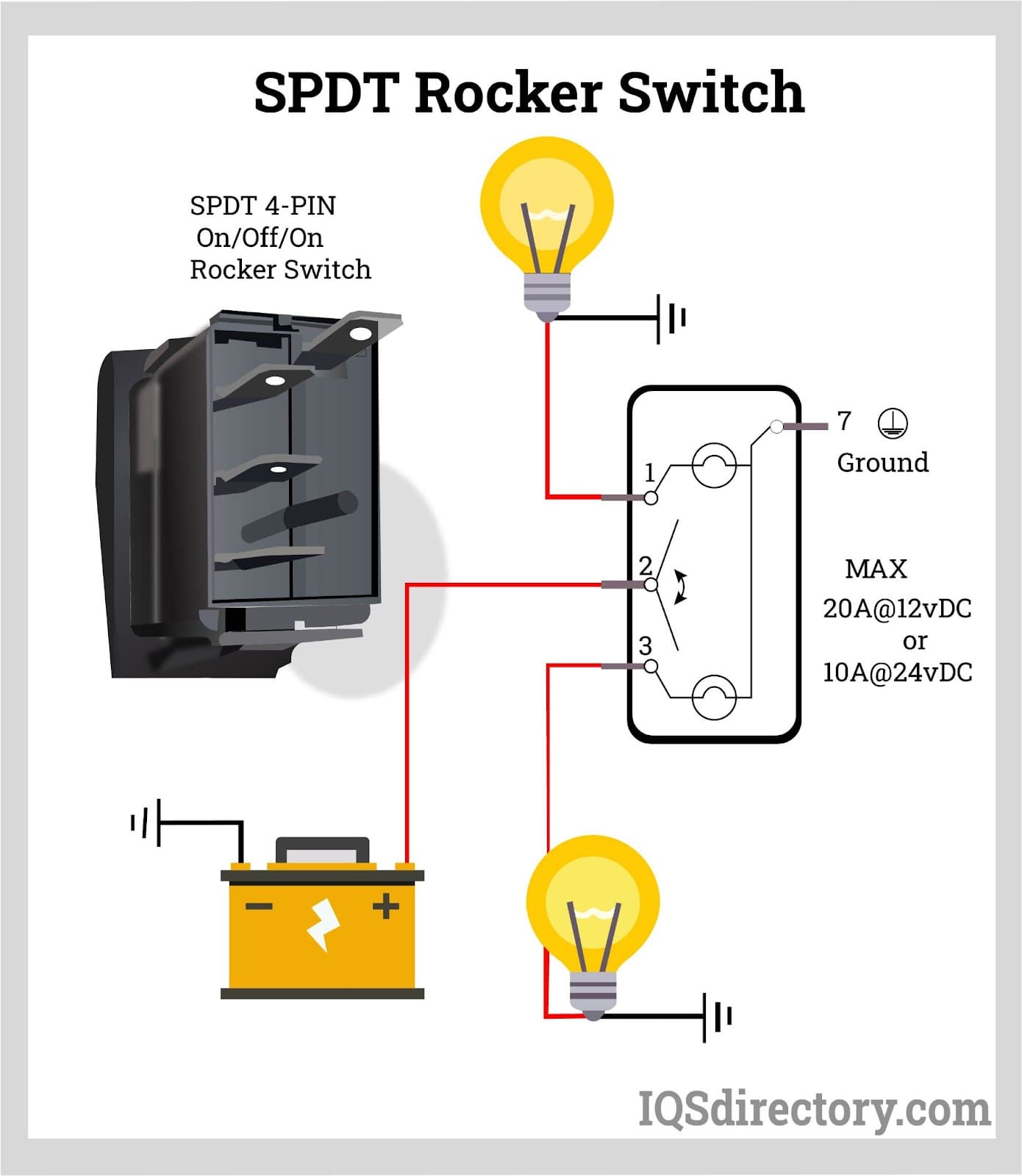

A single conductor can be connected to one of two additional single conductors using SPDT (single-pole, double-throw) rocker switches. Typically having three terminals, these switches are frequently used in pairs. Three-way switches are another name for SPDT switches.

Two source terminals are frequently connected to the corresponding output terminals using a double-pole, single-throw (DPST) switch, which has four terminals (but never to each other). DPST rocker switches make or break the connection between two circuit conductors in a single branch circuit. Normally, they have four terminals.

Two wires can be connected to two different circuits using DPDT (double-pole, double-throw) rocker switches. They typically come in versions with momentary and sustained contacts and have six terminals. In their (normal) condition, the contacts of a normally open (NO) rocker switch are either open or unconnected. Conversely, contacts in a normally- closed (NC) rocker switch are closed or connected when they are in their (normal) condition.

Switch Functions

Momentary ON - when the rocker switch is in the typical, open (NO) position, it depicts connections that break the circuit. Momentary OFF - when the rocker switch is in the typical, closed (NC) position, describes connections that create a circuit. Momentary center-NEUTRAL rocker switches with three positions feature an OFF or NEUTRAL function in the middle.

Specifications for Rocker Switches

As previously discussed, there are various types of rocker switches with different methods and functions of operation and feature numerous components. Below, we list a variety of other factors to consider when choosing an appropriate rocker switch for one's application:

- Dimensions, electrical ratings, terminal types, materials, and functions are among the crucial parameters to consider for rocker switches.

- electrical requirements

- present rating ceiling

- highest AC voltage

- highest DC voltage

- greatest power rating

- longest mechanical life

- dimensional requirements

- dimensions or diameter

- panel width and thickness

- terminal class

- feed-through design

- cable leads

- terminals soldered

- nut terminals,/li>

- blade or quick-connect terminals

- surface-mount engineering (SMT)

- slender PC pins

- straight PC pins

- PC side pins

Resources Used in the Construction of Rocker Switches

Most rocker switch bases and actuators are constructed from metal, thermoplastic, or plastic materials.

The Uses of Rocker Switches

- instrumentation front portions (shut-off switches)

- electrical apparatus (power supplies, power outlet strips, battery chargers)

- appliances for the home (small and large, vacuum cleaners, food equipment)

- computers and related devices (servers, network hubs, routers)

- audiovisual and telecommunications equipment

- industrial machinery (control panels, handling and packing machines, HVAC units, shop vacs)

- small apparatus (handheld devices, electric tools, office equipment)

- emergency lighting, generators, and lighting fixtures

- off-road automobiles

- medical devices (surgical tools, hospital beds, etc.)

- The toggle, paddle, and rocker-operated family of certified quality special-use electro-mechanical switches are covered by subsection specification EIA-520D000.

- Naval Electronic Systems Command, Department of the Navy, has approved this specification sheet, which is available for use by all Department of Defense Departments and Agencies.

Choosing the Right Rocker Switch Supplier

To make sure you have the most positive outcome when purchasing rocker switches from a rocker switch supplier, it is important to compare several companies using our directory of rocker switch suppliers. Each rocker switch supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each rocker switch business website using our proprietary website previewer for a better idea of what each company specializes in. Then, use our simple RFQ form to contact multiple rocker switch businesses with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

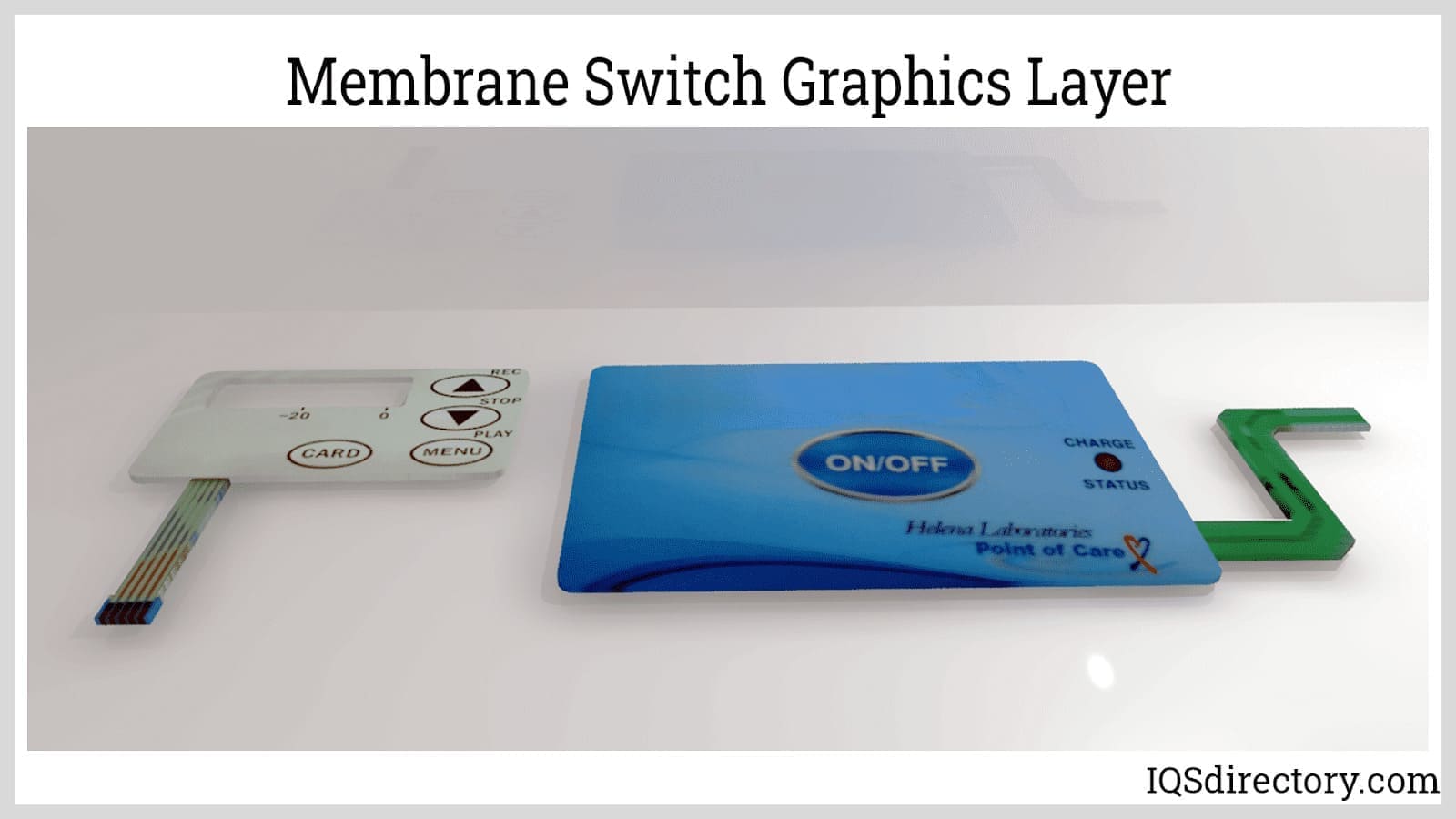

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services